1. Introduction to inverter generator

Inverter generator is a new type of generator that integrates electronics and variable frequency technology. Compared with the traditional generator set, its size and weight are reduced by about 50%, and the noise is also reduced a lot. This makes it suitable for many applications as a small portable power supply.

2. Machine panel analysis diagram

1. The portable handle is convenient to carry. 2. The choke wrench can quickly start the machine. 3. Easy to start, manually pull the recoil starting handle. 4. Oil circuit switch. 5. Generator maintenance panel. 6. Large area heat dissipation grille increases the heat dissipation of the muffler to reduce the temperature. 7. The muffler exhaust outlet effectively reduces the noise. 8. The oil tank cover with a sealing cover can effectively prevent volatilization. 9. Energy saving switch (upper: low speed: high speed) 10 Flameout switch (upper: startup lower: shutdown) 11 Safety grounding screw 12. Overcurrent protector 13 12V DC socket 14. AC output socket 15 AC output socket 16. 1: working indicator 2: overload indicator 3: oil shortage indicator 1. Spark plug removal and maintenance Spark plug with shielding cap, improve combustion efficiency and reduce carbon deposition 2. Rubber shock feet effectively reduce machine vibration and noise.

3. Machine startup steps:

1. Fill 93 # and 97 # gasoline and tighten the fuel tank cap.

2. Use a cross screwdriver to remove a total of one screw from the left front cover, which needs to be removed (friendly tips: there are two clips at the bottom of the left front cover, pay attention to the protection of the clips during assembly and disassembly, and reset and install the rear cover after adding oil, so that the sound insulation effect can be better achieved during use.).

3. Open the oil cap and fill in four stroke steam engine oil.

4. Turn the black knob to the (OPEN) position.

5. Turn the oil circuit switch to the (ON) position.

6. Press the choke to the (CHOKE) position.

7. Turn ENG.SW flameout switch on (ON).

8. Hold the starting handle until the machine starts.

9. After starting, slowly turn the choke to the RUN position.

Matters needing attention:

1. When the cold machine is started, it is necessary to start the air valve plate to the right, and the air valve plate can be directly started to the left.

2. How to use the high and low speed gears of the machine. When the ECON switch is turned to the ON position, it is the low speed automatic mode. The engine will automatically adjust the speed with the size of electrical load at any time. When the switch is turned to the OFF position, it is the high speed mode. It can directly carry electrical appliances with load.

3. It is recommended to install the left maintenance cover plate when the machine is in use, so that the sound insulation effect can be better.

4. Maintenance of the machine

1. The oil of the new machine needs to be replaced after a total of 50 hours of use.

2. If the machine is used frequently, it is recommended to change the oil every 1-3 months.

3. If the machine is used infrequently and occasionally, it is recommended to change the oil every six months.

4. Regularly remove the carbon deposit on the spark plug and check the gap (friendly tip: the spark plug is replaced every two years, and we will distribute an original spark plug randomly, and pay attention to keep it), as shown in the following figure:

5. Clean the sponge of air filter element regularly

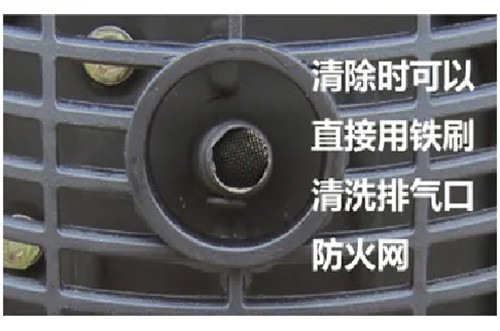

6. Regularly clean the carbon deposit on the fire screen at the exhaust outlet

5. Advantages of the machine:

1. Unique structure&excellent process: the appearance design is novel and beautiful, the internal process structure is unique and reasonable, and the company also has related patents for appearance design and internal structure.

2. Quiet and comfortable: The unique double-layer noise reduction system makes the noise of the digital generator set 3-9 decibels lower than that of the traditional generator set. It adopts the air duct designed by an internationally renowned professional design company, which makes the intake and exhaust more smooth, with less noise and mechanical vibration.

3. High quality&stability: the key component is its built-in microprocessor, which, with powerful modular design, will process and purify the original power generated by the generator, making the power output of the digital generator set very clean and stable. The power waveform of digital frequency conversion generator set is perfect sine waveform, so high-quality power is particularly suitable for electrical equipment and instruments that are sensitive to voltage and current fluctuations, such as computers, fax machines, printers, communication equipment, etc.

4. Green&environmental protection: It adopts a unique double-layer noise reduction structure. The running noise of the whole machine is 3-9 decibels lower than that of the traditional generator set. The efficient combustion system can minimize the emissions of harmful substances. Its emissions can meet the second stage standard of EPA (United States Environmental Protection Agency) in 2005. Compared with the traditional generator, it is a well deserved environment-friendly power generation equipment. Whether it is used in densely populated urban areas or camping in the wild, Or as a backup power supply in the home.

5. Economical&practical: It is equipped with a variety of automatic safety protection devices, such as overload protection, low oil pressure protection, etc., which greatly facilitates your operation and eliminates your worries. In addition, the unit is also equipped with a unique intelligent throttle, which can automatically adjust the speed according to the actual load changes, so that its fuel consumption is 20% - 40% lower than that of ordinary units, and its operation time is longer, bringing users more economic benefits At the same time, the service life of the whole machine is greatly extended.