Vacuum Brazed Saw Blade

√ Material: 65MN, selected high-quality diamond particles

√ Diameter: 100-900mm/4-36 inches

√ Working height: 5-15mm

√ Thickness: 1.0-6.4mm/0.04-0.250 inches

√ More Than 20 Years of Experience in Tool Industry

√ Own Plant Enables Cost Competitiveness and Production Flexibility

√ OEM/ODM Service

√ Authority Product Certification ISO9001/CE/GS

√ Various Product

√ Low MOQs, Fast Delivery

√ Good After-sales-service Let You No Worries

Vacuum Brazed Saw Blade a thin type brazing diamond saw blade is characterized in that: long open grooves are uniformly distributed along the circumference of the saw blade substrate, and diamond particles with metal composite coating are directly filled into the long open grooves uniformly distributed on the circumference of the saw blade substrate by brazing Because the diamond material in the utility model uses diamond particles with metal composite coating, the welding problem of non-metallic materials is effectively solved, the bonding force between the diamond particles and the saw blade matrix is greatly strengthened, the falling loss of diamond after impact is greatly reduced, and the utility model is very suitable for cutting precious materials, which can not only save raw materials, but also effectively improve the working efficiency.

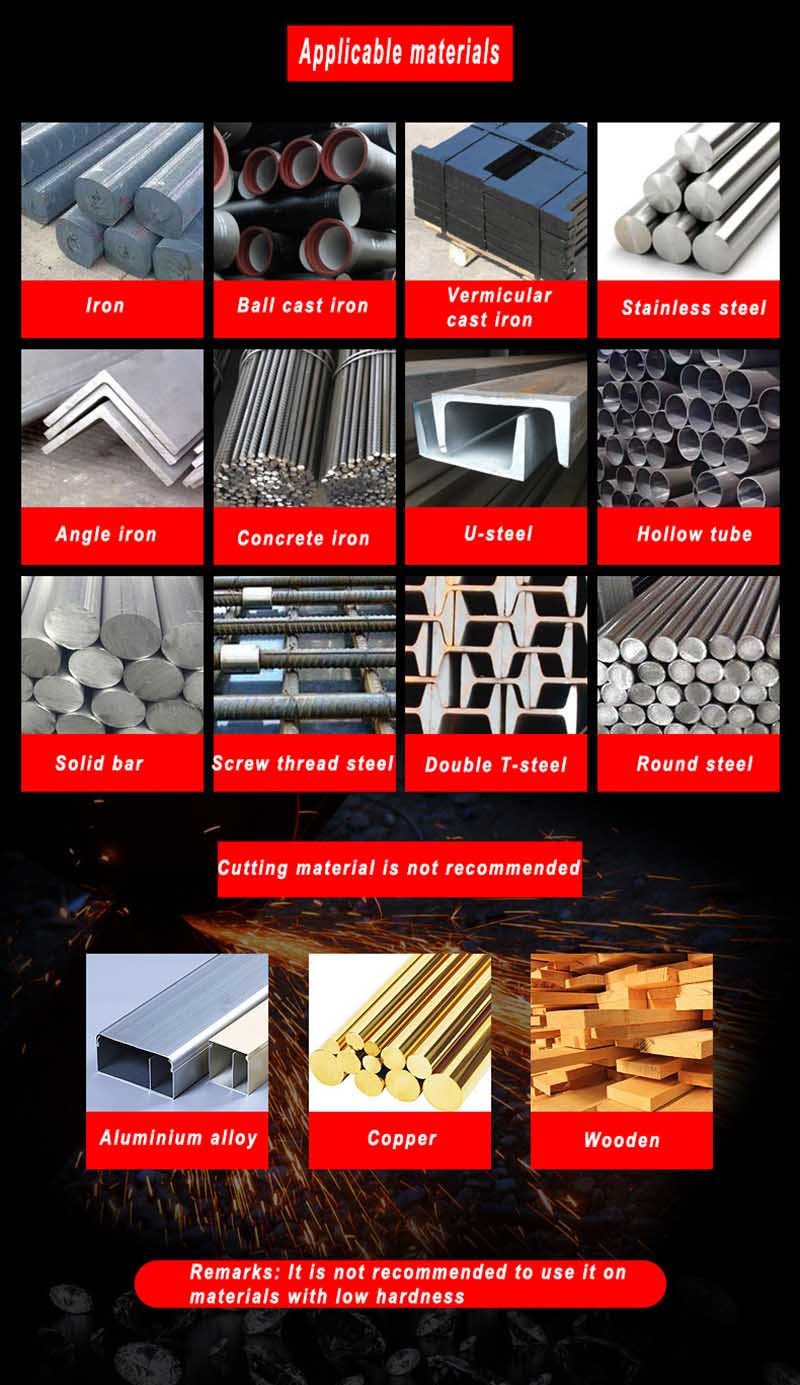

Application

Vacuum Brazed Saw Blade is used for cutting castings in the precision casting industry, such as nodular iron, gray iron, cast steel, etc. It is also suitable for cutting various hard and brittle materials and composite hard materials in emergency. Dry and wet mixed cutting of natural stone, artificial stone, ceramics, magnetic materials, concrete, quartz stone, glass, asphalt pavement and composite organic materials. It is used for cutting round pipe, square pipe, reinforcement, channel steel, I-beam, ductile iron, gray iron, cast steel and other castings in precision casting industry, as well as various hard brittle materials and composite hard materials. Wood board with nails, gypsum board, PVC pipe, bubble brick, rubber.

Feature and Advantage

Long service life, high toughness, high impact strength, high abrasion resistance, sharp cutting edge and durability of the abrasive effectively extend the service life of the tool.

The machining efficiency is high, and the exposed abrasive can reach 40-50% of the abrasive height, which makes the use of abrasive more fully and greatly improves the machining efficiency of tools.

High structural strength, high bonding strength between the abrasive and the substrate. The brazing temperature is about 1100 ℃, realizing the solid bonding between the diamond and the steel substrate, which is suitable for grinding.

It is safe and environmentally friendly. Traditional resin grinding discs will break during high-speed operation, while diamond grinding discs are made of integral steel matrix, which has strong hardness, high safety, less dust and no exhaust gas, ensuring the personal safety and occupational health of operators.

High cost performance. Brazed diamond abrasives are revolutionary and innovative products based on traditional products, with higher cost performance.

Why Choose Shall Vacuum Brazed Saw Blade

● Warranty one year

● Best quality materials

● Professional after-sales team

● Customizable products OEM, ODM

● Versatile applications, high performance, high frequency.

● In application, it is environment-friendly, pollution-free, dust-free, odorless, and free of debris, which greatly reduces the damage to workers' health.

● Sharp and durable cutting, safe use, smooth cutting line without edge collapse, ideal product for rapid engineering construction.

Shall Different Vacuum Brazed Saw Blade

Brazed segmented blade

Material: 65MN, selected high-quality diamond particles

Diameter: 300-900mm/ 12-36 inches

Working height: 8-15mm

Thickness: 3.2-6.4mm/ 0.125-0.250 inches

Speed: 1700-4300 RPM

Continuous Rim type(Wet)

Material: 65MN, selected high-quality diamond particles

Diameter: 100-150mm/ 4-6 inches

Working height: 4-15mm

Thickness: 2-2.2mm/ 0.08-0.095 inches

Speed: 10100-15300 RPM

Segmented type(Dry)

Material: 65MN, selected high-quality diamond particles

Diameter: 110-180mm/ 4-3/ 8-7 inches

Working height: 5mm

Thickness: 2-2.4mm/ 0.08-0.095 inches

Speed: 8500-13900 RPM

Vacuum brazed saw blade(Dry)

Material: 65MN, selected high-quality diamond particles

Diameter: 105-230mm/ 4-1/ 8-9 inches

Bore: 22.23mm

Thickness: 1.0-1.6mm/ 0.04-0.06 inches

Speed: 6600-14500 RPM

Why Choose SHALL As Your Vacuum Brazed Saw Blad Supplier?

✔ More than 20 years of experience in the tools industry.

✔ Full range of tools, power tools, power tools accessories, garden tools, hand tools, tools set, etc. More than 10,000 items, can satisfy all the tools requirements, bring wide market benefits to customers.

✔ Professional R&D and Sales Service Team.

✔ Self-owned factory with competitive and reasonable price, lifting our production quality.

✔ High quality production and design standards for safe and reliable use. Built to international standards CE/GS/EMC/ETL/ROHS/UL.

✔ ODM&OEM Customization services.

✔ Strict Quality Control.

✔ Low MOQs, fast delivery.

Hot Tags: vacuum brazed saw blade, China, manufacturers, suppliers, factory, suppliers, wholesale,

Send Inquiry